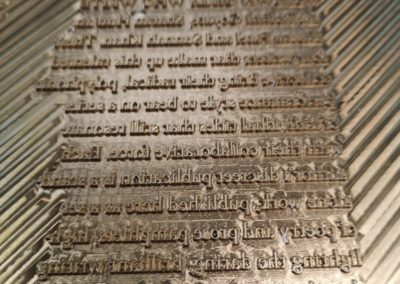

All our foil dies are engraved on our high-speed CNC machines for the most accurate and clean finish to our customers products.

All our foil dies are engraved on our high-speed CNC machines for the most accurate and clean finish to our customers products.

We offer a hybrid brass and aluminium combi foil die as well solid brass.

One of the benefits of our hybrid dice is weight, making it easier for the operator to handle and reducing the cost to the customer.

We’ve been producing and using this product for over ten years and found the results and lifespan of the dies to be the same as solid brass.

We can also provide a 3D image of how the die itself will appear before machining the actual product.

The dies are normally machined on 6.35mm Aluminium but other sizes can be used if specified by the customer. Every emboss-deboss die will come with an epoxy resin force which have greater durability than the UV generated forces or “flexi force”.

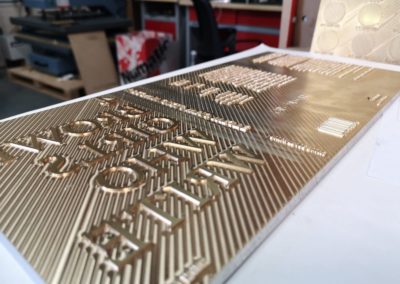

Fluted dies are a way of introducing two processes into one – foil and emboss.

The design will determine the depth of finish to emboss, while using a location pin system, which allows the operator to locate the force exactly in to position, cuts down make ready times and the use of Prago therm.

The standard depth of the dies are 6.35mm (1/4”) but we can engrave to what the customer desires within tolerances.

Texture dies are a way of adding something different to your design, whether it be a security logo or a different finish to your design.

These textures can also be introduced into flutes and emboss dies.

The processes are the same in depths of the die remain at 6.35mm (¼”) standard or to the customers desired depth.

Texture booklets are available on request.

When the dies are completed, we cut the dies edges to the customer’s desired angles.

Info From The Customer

We ask the customer to supply as clean an image as possible in PDF or Tiff format preferably with a minimum of 600dpi, black and white with clear instructions of what processes are required.

We like to work with our customers to understand exactly what they want to achieve the best finished product possible.

“Every impression counts”